Page 62 - Osawa_Update_2023

P. 62

G2 - General purpose - Square

CUTTING PARAMETERS

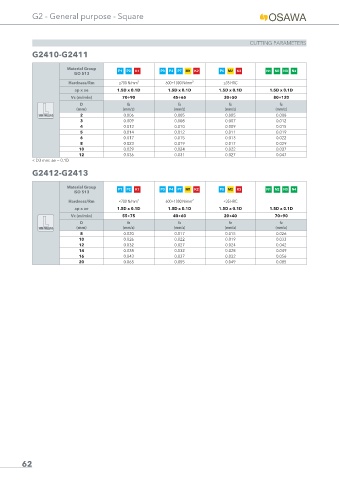

G2410-G2411 M1 N1 M2 N2 M3 N3

N1

N3

N2

N4

M1 M2 P1 S1 M3 M4 M7 N7 P2 S2 M5 N5 P3 S3

Material Group P1 P2 K1 H1 H1 P3 P4 P7 M1 K2 H2 H2 P5 M2 N2 H3 H3M1 M2 M3 M4 N4

S2

S5

S7

S4

S3

S1

N1

N1

N2

N3

K3

ISO 513

K1 K2 K3 H3 H3H4 H4H7 H7 K5 H5 H5 P1 P2 P3 P4 S4

H1 H1H2 H2

S1

S2

S3

S2

P2

K7

K4

S1

P1

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC

H2 H2

K1

K2

K3

K4

K2

ap x ae 1.5D x 0.1D 1.5D x 0.1D H1 H1 1.5D x 0.1D K1 H1 H1H2 H2H3 H3H4 H4

1.5D x 0.1D

Vc (m/min) 70÷90 45÷65 30÷50 80÷120

D fz fz fz fz

(mm) (mm/z) (mm/z) (mm/z) (mm/z)

SIDE MILLING 2 0.006 0.005 0.005 0.008

3 0.009 0.008 0.007 0.012

4 0.012 0.010 0.009 0.015

5 0.014 0.012 0.011 0.019

6 0.017 0.015 0.013 0.022

8 0.023 0.019 0.017 0.029

10 0.029 0.024 0.022 0.037

12 0.036 0.031 0.027 0.047

< D3 mm: ae = 0.1D

G2412-G2413 M1 N1 M2 N2 M3 N3

M1 M2 N2 S1 M3 M4 M7 N7 P2 S2 M5 N5 P3 S3

N1

N4

N3

P1

Material Group P1 P2 K1 H1 H1 P3 P4 P7 M1 K2 H2 H2 P5 M2 K3 H3 H3M1 M2 M3 M4 N4

N2

N1

S5

S1

N3

N2

S2

N1

S7

S3

S4

ISO 513

H1 H1H2 H2

K4

K1 K2 K3 H3 H3H4 H4H7 H7 K5 H5 H5 P1 P2 S2 P4 S4

K7

S1

S1

P3

S3

S2

P2

P1

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC

K3

K4

K2

K2

K1

H2 H2

ap x ae 1.5D x 0.1D 1.5D x 0.1D H1 H1 1.5D x 0.1D K1 H1 H1H2 H2H3 H3H4 H4

1.5D x 0.1D

Vc (m/min) 55÷75 40÷60 20÷40 70÷90

D fz fz fz fz

SIDE MILLING (mm) (mm/z) (mm/z) (mm/z) (mm/z)

8 0.020 0.017 0.015 0.026

10 0.026 0.022 0.019 0.033

12 0.032 0.027 0.024 0.042

14 0.038 0.032 0.028 0.049

16 0.043 0.037 0.032 0.056

20 0.065 0.055 0.049 0.085

62