Page 422 - Catalogue-Osawa-2021

P. 422

HF UNI - Variable Helix and unequal pitch - Corner radius

CUTTING PARAMETERS

INFO

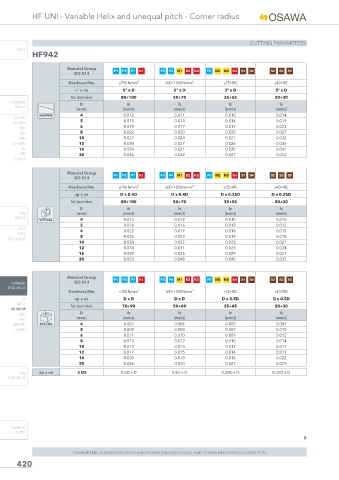

HF942

Material Group P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5

ISO 513

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC

° x ae 5° x D 5° x D 3° x D 3° x D

Vc (m/min) 80÷100 50÷70 35÷55 20÷30

CARBIDE D fz fz fz fz

DRILLS

(mm) (mm/z) (mm/z) (mm/z) (mm/z)

RAMPING 4 0.012 0.011 0.010 0.014

PU-HPU

5 0.015 0.014 0.014 0.019

TA-4HTA

6 0.019 0.017 0.017 0.023

SUH

ALH 8 0.022 0.020 0.020 0.027

HRC 10 0.027 0.024 0.023 0.032

SUH MINI 12 0.030 0.027 0.026 0.036

HL 16 0.034 0.031 0.030 0.041

HSD 20 0.046 0.042 0.041 0.056

C-SD-TA

Material Group P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5

ISO 513

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC

ap x ae D x 0.4D D x 0.4D D x 0.25D D x 0.25D

Vc (m/min) 80÷100 50÷70 35÷55 20÷30

D fz fz fz fz

HSS (mm) (mm/z) (mm/z) (mm/z) (mm/z)

DRILLS VERTICAL 4 0.014 0.012 0.010 0.010

5 0.018 0.016 0.013 0.012

LFTA

6 0.022 0.019 0.016 0.015

SUTA

8 0.026 0.023 0.019 0.018

HSS-HSS/CO

10 0.030 0.027 0.023 0.021

12 0.034 0.031 0.026 0.024

16 0.039 0.035 0.029 0.027

20 0.053 0.048 0.040 0.037

Material Group P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5

CARBIDE ISO 513

END-MILLS

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC

G2 ap x ae D x D D x D D x 0.5D D x 0.5D

MDTA

Vc (m/min) 70÷90 50÷60 35÷45 20÷30

HF VH/UP

MEF D fz fz fz fz

(mm) (mm/z) (mm/z) (mm/z) (mm/z)

ALU

MEX/MH DRILLING 4 0.007 0.006 0.005 0.007

UH/MH 5 0.009 0.008 0.007 0.010

6 0.011 0.010 0.009 0.012

8 0.013 0.012 0.010 0.014

10 0.015 0.014 0.012 0.017

12 0.017 0.015 0.014 0.019

16 0.020 0.018 0.016 0.022

20 0.026 0.024 0.021 0.029

HSS ap x ae ≤ D5 0.5D x D 0.5D x D 0.25D x D 0.25D x D

END-MILLS

CARBIDE

BURRS

PARAMETERS SUGGESTED WITH HIGH POWER MILLING CHUCK AND STABLE MACHINING CONDITION

420

21/10/2021 12:14:30

Libro 1.indb 420

Libro 1.indb 420 21/10/2021 12:14:30