Page 49 - Osawa_Update_2023

P. 49

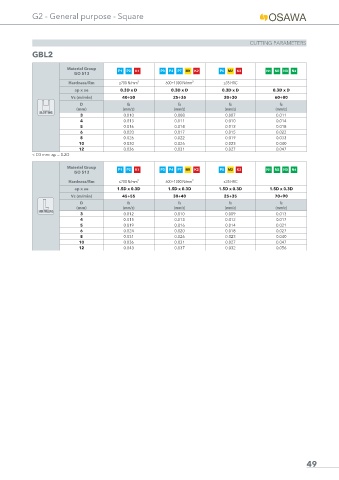

G2 - General purpose - Square

CUTTING PARAMETERS

GBL2 M1 N1 M2 N2 M3 N3

N2

N3

M1 M2 P1 S1 M3 M4 M7 N7 P2 S2 M5 N5 P3 S3

N1

N4

Material Group P1 P2 K1 H1 H1 P3 P4 S4 M1 K2 H2 H2 P5 M2 K3 H3 H3M1 M2 M3 M4 N4

S1

S7

S5

S3

S2

P7

N2

N3

N1

N1

N2

ISO 513

P2

K1 K2 K3 K4 K7 P1 S1 K5 H5 H5 P1 P2 P3 P4 S4

S2

S2

H1 H1H2 H2

H3 H3H4 H4H7 H7

S1

S3

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC

K3

K2

K4

K2

0.3D x D

ap x ae 0.3D x D 0.3D x D K1 H1 H1 0.3D x D H2 H2 K1 H1 H1H2 H2H3 H3H4 H4

Vc (m/min) 40÷50 25÷35 20÷30 60÷80

D fz fz fz fz

(mm) (mm/z) (mm/z) (mm/z) (mm/z)

SLOTTING

3 0.010 0.008 0.007 0.011

4 0.013 0.011 0.010 0.014

5 0.016 0.014 0.012 0.018

6 0.020 0.017 0.015 0.022

8 0.026 0.022 0.019 0.033

10 0.030 0.026 0.023 0.040

12 0.036 M1 N1 0.031 M2 N2 0.027 M3 N3 0.047

< D3 mm: ap = 0.2D

N4

N3

M1 M2 P1 S1 M3 M4 M7 N7 P2 S2 M5 N5 P3 S3

N2

N1

Material Group P1 P2 K1 H1 H1 P3 P4 S4 M1 K2 H2 H2 P5 M2 K3 H3 H3M1 M2 M3 M4 N4

S7

N3

N1

N2

S5

N2

N1

S3

S2

P7

S1

ISO 513

S3

S1

P3

K1 K2 K3 K4 K7 P1 S1 K5 P2 S2 P1 P2 S2 P4 S4

H3 H3H4 H4H7 H7

H1 H1H2 H2

H5 H5

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC

K4

H1 H1H2 H2H3 H3H4 H4

K3

H2 H2

K2

K1

ap x ae 1.5D x 0.3D 1.5D x 0.3D H1 H1 1.5D x 0.3D K1 K2 1.5D x 0.3D

Vc (m/min) 45÷55 30÷40 25÷35 70÷90

D fz fz fz fz

(mm) (mm/z) (mm/z) (mm/z) (mm/z)

SIDE MILLING

3 0.012 0.010 0.009 0.013

4 0.015 0.013 0.012 0.017

5 0.019 0.016 0.014 0.021

6 0.024 0.020 0.018 0.027

8 0.031 0.026 0.023 0.040

10 0.036 0.031 0.027 0.047

12 0.043 0.037 0.032 0.056

49