Page 439 - Catalogue-Osawa-2021

P. 439

HF UNI - Variable helix - Corner radius

CUTTING PARAMETERS

INFO

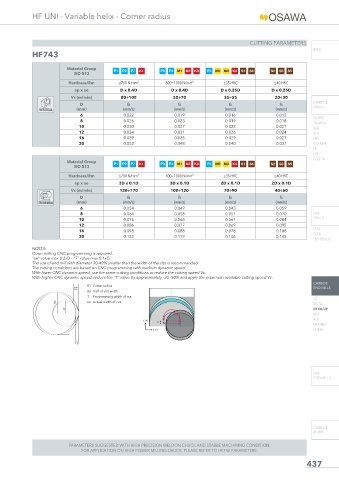

HF743

Material Group P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5

ISO 513

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC

ap x ae D x 0.4D D x 0.4D D x 0.25D D x 0.25D

Vc (m/min) 80÷100 50÷70 35÷55 20÷30

CARBIDE

D fz fz fz fz DRILLS

VERTICAL (mm) (mm/z) (mm/z) (mm/z) (mm/z)

6 0.022 0.019 0.016 0.015

PU-HPU

8 0.026 0.023 0.019 0.018

TA-4HTA

10 0.030 0.027 0.023 0.021

SUH

12 0.034 0.031 0.026 0.024 ALH

16 0.039 0.035 0.029 0.027 HRC

20 0.053 0.048 0.040 0.037 SUH MINI

HL

HSD

C-SD-TA

Material Group P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5

ISO 513

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC

ap x ae 3D x 0.1D 3D x 0.1D 2D x 0.1D 2D x 0.1D

Vc (m/min) 130÷170 100÷120 70÷90 40÷60

D fz fz fz fz

TROCHOIDAL (mm) (mm/z) (mm/z) (mm/z) (mm/z)

6 0.054 0.049 0.043 0.059

8 0.064 0.058 0.051 0.070 HSS

DRILLS

10 0.076 0.068 0.061 0.084

12 0.086 0.077 0.069 0.095

LFTA

16 0.098 0.088 0.078 0.108

SUTA

20 0.132 0.119 0.106 0.145

HSS-HSS/CO

NOTES:

Down milling CNC programming is required.

“ae” value max 0.2xD - “T” value max 0.1xD.

The use of end mill with diameter 30-40% smaller than the width of the slot is recommended.

The cutting conditions are based on CNC programming with medium dynamic speed.

With lower CNC dynamic speed, use the same cutting conditions or reduce the cutting speed Vc.

With higher CNC dynamic speed, reduce the “T” value by approximately -30 -50% and apply the maximum available cutting speed Vc.

CARBIDE

ae R1 Cutter radius END-MILLS

R2 Half of slot width

T Programming width of cut G2

R2 ae Actual width of cut MDTA

R1 HF VH/UP

MEF

ALU

Y (+)

Y

MEX/MH

X (+) UH/MH

T

HSS

END-MILLS

CARBIDE

BURRS

PARAMETERS SUGGESTED WITH HIGH PRECISION WELDON CHUCK AND STABLE MACHINING CONDITION.

FOR APPLICATION ON HIGH POWER MILLING CHUCK, PLEASE REFER TO HF742 PARAMETERS.

437

21/10/2021 12:14:56

Libro 1.indb 437

Libro 1.indb 437 21/10/2021 12:14:56