Page 401 - Catalogue-Osawa-2021

P. 401

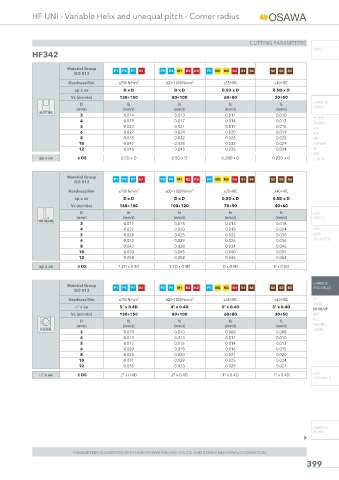

HF UNI - Variable Helix and unequal pitch - Corner radius

CUTTING PARAMETERS

INFO

HF342

Material Group P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5

ISO 513

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC

ap x ae D x D D x D 0.5D x D 0.5D x D

Vc (m/min) 130÷150 80÷100 60÷80 30÷50

CARBIDE

D fz fz fz fz

(mm) (mm/z) (mm/z) (mm/z) (mm/z) DRILLS

SLOTTING

3 0.014 0.013 0.011 0.010

PU-HPU

4 0.019 0.017 0.014 0.013

TA-4HTA

5 0.023 0.021 0.017 0.016

SUH

6 0.027 0.024 0.020 0.019 ALH

8 0.035 0.032 0.026 0.025 HRC

10 0.042 0.038 0.032 0.029 SUH MINI

12 0.048 0.043 0.036 0.034 HL

HSD

ap x ae ≤ D5 0.5D x D 0.5D x D 0.25D x D 0.25D x D C-SD-TA

Material Group P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5

ISO 513

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC

ap x ae D x D D x D 0.5D x D 0.5D x D

Vc (m/min) 160÷180 100÷120 70÷90 40÷60

D fz fz fz fz HSS

(mm) (mm/z) (mm/z) (mm/z) (mm/z) DRILLS

SIDE MILLING

3 0.017 0.015 0.013 0.018

4 0.022 0.020 0.018 0.024 LFTA

5 0.028 0.025 0.022 0.030 SUTA

HSS-HSS/CO

6 0.032 0.029 0.026 0.036

8 0.042 0.038 0.034 0.046

10 0.050 0.045 0.040 0.055

12 0.058 0.052 0.046 0.063

ap x ae ≤ D5 1.2D x 0.3D 1.2D x 0.3D D x 0.2D D x 0.2D

CARBIDE

Material Group P1 P2 P7 K1 P3 P4 M1 K2 K3 P5 M2 M3 K4 S1 S4 S2 S3 S5 END-MILLS

ISO 513

Hardness/Rm ≤700 N/mm² 600÷1000 N/mm² ≤35 HRC ≤40 HRC G2

MDTA

° x ae 5° x 0.4D 4° x 0.4D 3° x 0.4D 3° x 0.4D

HF VH/UP

Vc (m/min) 130÷150 80÷100 60÷80 30÷50 MEF

ALU

D fz fz fz fz

(mm) (mm/z) (mm/z) (mm/z) (mm/z) MEX/MH

HELICAL UH/MH

3 0.010 0.010 0.008 0.008

4 0.013 0.013 0.011 0.010

5 0.017 0.016 0.014 0.013

6 0.020 0.018 0.016 0.015

8 0.025 0.024 0.021 0.020

10 0.031 0.029 0.025 0.024

12 0.035 0.033 0.029 0.027

° x ae ≤ D5 2° x 0.4D 2° x 0.4D 1° x 0.4D 1° x 0.4D HSS

END-MILLS

CARBIDE

BURRS

PARAMETERS SUGGESTED WITH HIGH POWER MILLING CHUCK AND STABLE MACHINING CONDITION

399

21/10/2021 12:13:55

Libro 1.indb 399

Libro 1.indb 399 21/10/2021 12:13:55