Page 30 - Catalogue-Osawa-2021

P. 30

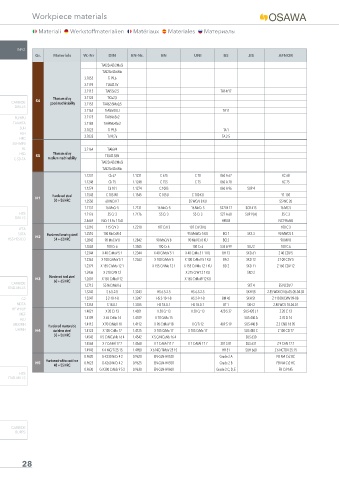

Workpiece materials

Materiali Werkstoffmaterialien Matériaux Materiales Материалы

INFO

Gr. Materials W.-Nr DIN EN-Nr. EN UNI BS JIS AFNOR

TiAl2Sn4Zr2MoSi

TiAl2Sn4Zr6Mo

3.7055 Ti 99,6

3.7195 Ti3Al2.5V

3.7115 TiAl5Sn2.5 TA14/17

Titanium alloy 3.7124 TiCu2,5

CARBIDE S4 good machinability 3.7155 TiAl6Zr5Mo0,5

DRILLS

3.7165 TiAl6V4 ELI TA11

PU/HPU 3.7175 TiAl6V6Sn2

TA/4HTA 3.7185 TiAl4Mo4Sn2

SUH

3.7025 Ti 99,8 TA 1

ALH

3.7035 Ti 99,7a TA 2-5

HRC

SUH MINI

HL 3.7164 TiAl6V4

HSD Titanium alloy

S5 Ti5Al2.5SN

C-SD-TA medium machinability

TiAl2Sn4Zr2MoSi

TiAl2Sn4Zr6Mo

1.1231 Ck 67 1.1231 C 67S C 70 060 A 67 XC 68

1.1248 Ck 75 1.1248 C 75S C 75 060 A 78 XC 75

1.1274 Ck 101 1.1274 C 100S 060 A 96 SUP 4

Hardened steel 1.1545 C 105 W1 1.1545 C 105U C 100 KU Y1 105

H1

50 ÷ 56 HRC 1.2550 60 WCrV 7 55 WCrV 8 KU 55 WC 20

1.7131 16 MnCr 5 1.7131 16 MnCr 5 16 MnCr 5 527 M 17 SCR 415 16 MC 5

HSS 1.7176 55 Cr 3 1.7176 55 Cr 3 55 Cr 3 527 A 60 SUP 9 (A) 55 C 3

DRILLS

2.4669 NiCr 15 Fe 7 TiAl HR505 NC19FeNB

1.2210 115 CrV 3 1.2210 107 CrV 3 107 CrV 3 KU 100 C 3

LFTA

SUTA Hardened bearing steel 1.2510 100 MnCrW 4 95 MnWCr 5 KU BO 1 SKS 3 90 MWCV 5

H2

HSS-HSS/CO 54 ÷ 62 HRC 1.2842 90 MnCrV 8 1.2842 90 MnCrV 8 90 MnVCr 8 KU BO 2 90 MV 8

1.3505 100 Cr 6 1.3505 100 Cr 6 100 Cr 6 534 A 99 SUJ 2 100 C 6

1.2344 X 40 CrMoV 5 1 1.2344 X 40 CrMoV 5 1 X 40 CrMo 5 1 1 KU BH 13 SKD 61 Z 40 CDV 5

1.2363 X 100 CrMoV 5 1 1.2363 X 100 CrMoV 5 X 100 CrMoV 5 1 KU BA 2 SKD 12 Z 100 CDV 5

1.2379 X 155 CrVMo 12 1 X 155 CrVMo 12 1 X 155 CrVMo 12 1 KU BD 2 SKD 11 Z 160 CDV 12

1.2436 X 210 CrW 12 X 215 CrW 12 1 KU SKD 2

Hardened tool steel

H3 1.2601 X 165 CrMoV 12 X 165 CrMoW 12 KU

CARBIDE 60 ÷ 65 HRC 1.2713 55 NiCrMoV 6 SKT 4 55 NCDV 7

END-MILLS

1.3243 S 6-5-2-5 1.3243 HS 6-5-2-5 HS 6-5-2-5 SKH 55 Z 85 WDKCV 06-05-05-04-02

G2 1.3247 S 2-10-1-8 1.3247 HS 2-10-1-8 HS 2-9-1-8 BM 42 SKH 51 Z 110 DKCWV 09-08-

MDTA 1.3355 S 18-0-1 1.3355 HS 18-0-1 HS 18-0-1 BT 1 SKH 2 Z 80 WCV 18-04-01

HF VH/UP

1.4021 X 20 Cr 13 1.4021 X 20 Cr 13 X 20 Cr 13 420 S 37 SUS 420 J 1 Z 20 C 13

MEF

1.4109 X 65 CrMo 14 1.4109 X 70 CrMo 15 SUS 440 A Z 70 D 14

ALU

MEX/MH 1.4112 X 90 CrMoV 18 1.4112 X 90 CrMoV 18 X CrTi 12 409 S 19 SUS 440 B Z 2 CND 18 05

Hardened martensitic

UH/MH H4 stainless steel 1.4125 X 105 CrMo 17 1.4125 X 105 CrMo 17 X 105 CrMo 17 SUS 440 C Z 100 CD 17

50 ÷ 56 HRC

1.4542 X 5 CrNiCuNb 16 4 1.4542 X 5 CrNiCuNb 16 4 SUS 630

1.4568 X 7 CrNiAl 17 7 1.4568 X 7 CrNiAl 17 7 X 7 CrNiAl 17 7 301 S 81 SUS 631 Z 9 CAN 17.7

1.4943 X 4 NiCrTi 25 15 1.4980 X 6 NiCrTiMoV 25 15 HR 51 SUH 660 Z 6 NCTDV 25.15

0.9620 G-X330 NiCr 4 2 0.9620 EN-GJN-HV520 Grade 2 A FB Ni4 Cr2 BC

Hardened white cast iron

H5 0.9625 G-X260 NiCr 4 2 0.9625 EN-GJN-HV550 Grade 2 B FB Ni4 Cr2 HC

48 ÷ 55 HRC

0.9630 G-X300 CrNiSi 9 5 2 0.9630 EN-GJN-HV600 Grade 2 C, D, E FB Cr9 Ni5

HSS

END-MILLS

CARBIDE

BURRS

28

21/10/2021 12:07:12

Libro 1.indb 28 21/10/2021 12:07:12

Libro 1.indb 28