Page 4 - Osawa Update Catalogue 2019

P. 4

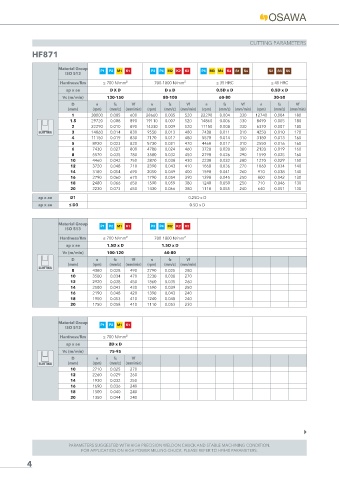

CUTTING PARAMETERS

HF871 M1 N1 M2 M3 N3 M4 N4

N2

S2

N3

M1 M2 N2 P1 S1 M3 M4 N4 P2 P3 S3 M5 N5 M1 M4 N4 M2 M3 M5 N5

N1

N2

N3

S4

P4

N1

Material Group P1 P2 M1 K1 H1 H1 P3 P4 M2 K2 K3 P5 M3 M4 K4 P4 S4 P2 P3 P5 S5

S2

S5

S1

N1

N3

N4

H4 H4

S1

P1

S3

N2

S3

S2

S4

H2 H2H3 H3

ISO 513

K1 K2 P1 S1 K3 H3 H3H4 H4 K5 H5 H5 K1 K4 K2 K3 K5

H1 H1H4 H4

S4

S2

P4

H2 H2H3 H3H5 H5

P2

K4

P3

H1 H1H2 H2

S3

Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm² ≤ 35 HRC ≤ 40 HRC

H3 H3H4 H4

K1

K2

K4

ap x ae D X D H1 H1 D x D H2 H2 K3 0.5D x D 0.5D x D

Vc (m/min) 130-150 80-100 60-80 30-50

D n fz Vf n fz Vf n fz Vf n fz Vf

(mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min)

1 30000 0.005 600 28660 0.005 520 22290 0.004 330 12740 0.004 180

1.5 29720 0.008 890 19110 0.007 520 14860 0.006 330 8490 0.005 180

2 22290 0.010 890 14330 0.009 520 11150 0.008 330 6370 0.007 180

SLOTTING 3 14860 0.014 830 9550 0.013 480 7430 0.011 310 4250 0.010 170

4 11150 0.019 830 7170 0.017 480 5570 0.014 310 3180 0.013 160

5 8920 0.023 820 5730 0.021 470 4460 0.017 310 2550 0.016 160

6 7430 0.027 800 4780 0.024 460 3720 0.020 300 2120 0.019 160

8 5570 0.035 780 3580 0.032 450 2790 0.026 290 1590 0.025 160

10 4460 0.042 750 2870 0.038 430 2230 0.032 280 1270 0.029 150

12 3720 0.048 710 2390 0.043 410 1860 0.036 270 1060 0.034 140

14 3180 0.054 690 2050 0.049 400 1590 0.041 260 910 0.038 140

16 2790 0.060 670 1790 0.054 390 1390 0.045 250 800 0.042 130

18 2480 0.066 650 1590 0.059 380 1240 0.050 250 710 0.046 130

20 2230 0.073 650 1430 0.066 380 1110 0.055 240 640 0.051 130

ap x ae D1 0.25D x D

ap x ae ≤ D3 0.5D x D

N2

M1 N1 M2 M3 N3

N3

N1

M1 M2 N2 P1 S1 M3 M4 N4 P2 P3 S3

S2

Material Group P1 P2 M1 K1 H1 H1 P3 P4 M2 N2 H2 H2H3 H3

N1

K2

S4

S3

K3

S2

S1

ISO 513

H1 H1H2 H2

K4

K1 K2 P1 S1 K3 H3 H3H4 H4

P2

S2

Hardness/Rm ≤ 700 N/mm² 700-1000 N/mm²

K1

K2

ap x ae 1.5D x D H1 H1 1.5D x D H2 H2

Vc (m/min) 100-120 60-80

D n fz Vf n fz Vf

(mm) (rpm) (mm/z) (mm/min) (rpm) (mm/z) (mm/min)

SLOTTING

8 4380 0.028 490 2790 0.025 280

10 3500 0.034 470 2230 0.030 270

12 2920 0.038 450 1860 0.035 260

14 2500 0.043 430 1590 0.039 250

16 2190 0.048 420 1390 0.043 240

18 1950 0.053 410 1240 0.048 240

20 1750 0.058 410 1110 0.053 230

M1 N1

N1

M1 M2 N2 P1 S1

Material Group P1 P2 M1 N1 H1 H1

K1

S2

S1

ISO 513

K1 K2 P1 S1

H1 H1H2 H2

Hardness/Rm ≤ 700 N/mm²

K1

ap x ae 2D x D H1 H1

Vc (m/min) 75-95

D n fz Vf

SLOTTING (mm) (rpm) (mm/z) (mm/min)

10 2710 0.025 270

12 2260 0.029 260

14 1930 0.032 250

16 1690 0.036 240

18 1500 0.040 240

20 1350 0.044 240

PARAMETERS SUGGESTED WITH HIGH PRECISION WELDON CHUCK AND STABLE MACHINING CONDITION.

FOR APPLICATION ON HIGH POWER MILLING CHUCK, PLEASE REFER TO HF840 PARAMETERS.

4